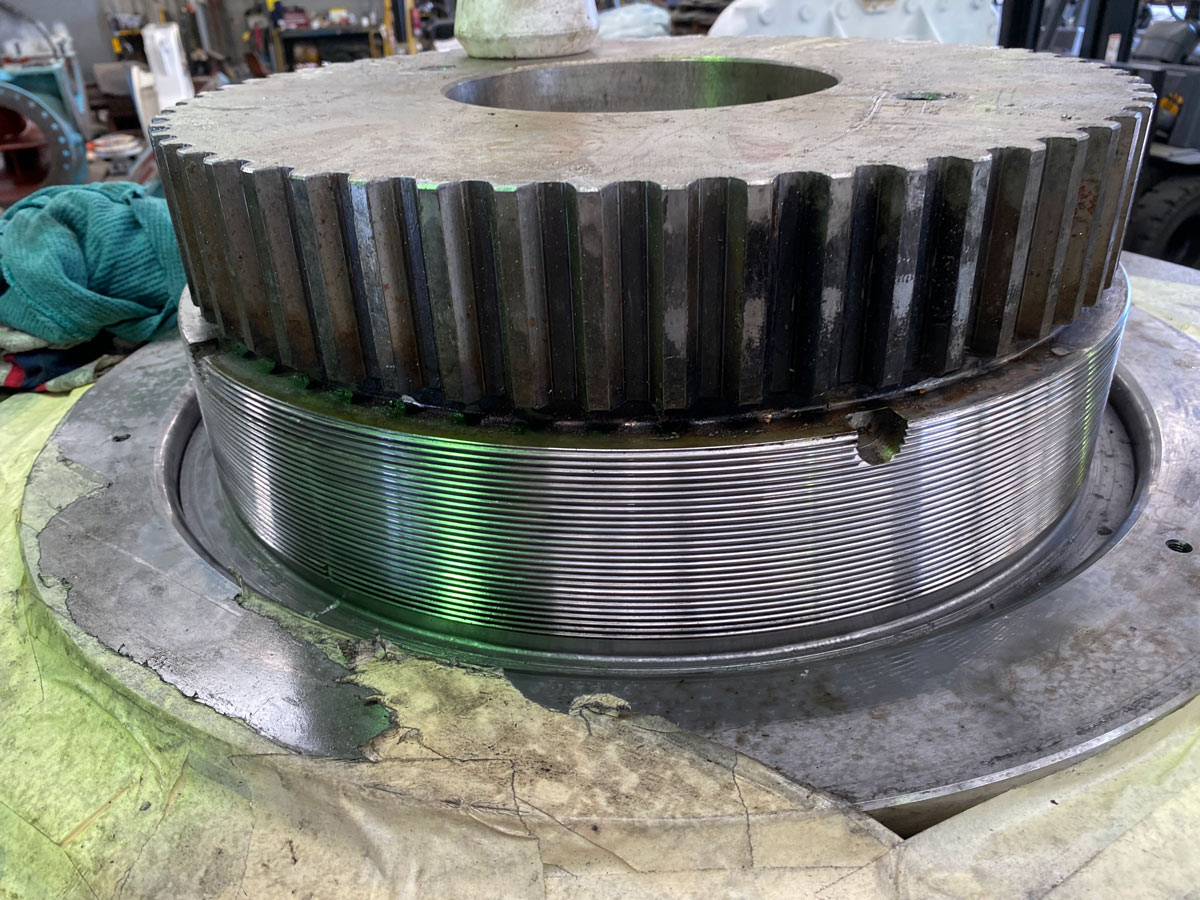

CAT Excavator Final Drive, Seized Nut Removal

Simple problems don’t always have simple solutions. This week the Prime Engineering team tackled a stubborn nut that had sealed important machinery inside the casing of a CAT excavator. Doing the job wrong could have caused costly damages; that’s why our client trusted our sturdy hands for perfection.

The Challenge:

Our client was scheduled to work on a final drive unit from a CAT excavator. The parts they needed to work on were encased in a housing by a large nut that sealed off access. The nut on this particular unit had seized onto the thread, thus locking in the internal parts. The challenge was to machine off the nut without damaging the internal thread on the drive housing.

The Results:

With the nut and seized metal removed from the thread, the housing was saved. Our client could now access the internal parts to complete the work they were previously locked away from. We are waiting to see if the client needs us to make a new nut.