Large component machining is the practice of machining and fabricating large and heavy parts. This can involve drilling, milling, threading, turning, tapping and horizontal boring work. At Prime Engineering, we have all of the machinery and expertise necessary to ensure that, regardless of the size of your component, we can still deliver the same exceptional level of detail, accuracy, and care. Bring us your large component or part and we will craft a tailor-made solution to suit all of your needs!

Below are just some of the pieces of equipment we use for large component machining:

Lathes

Our lathes have the ability to turn very large parts, rotating them around an axis of rotation in order to cut, drill and knurl. Each of these processes uses the axis to create symmetry on your component.

Milling Machines

Our milling machines can complete large and heavy-duty operations with extreme precision. This machine will advance into your large component and use rotary cutters to remove material either using one or multiple axes.

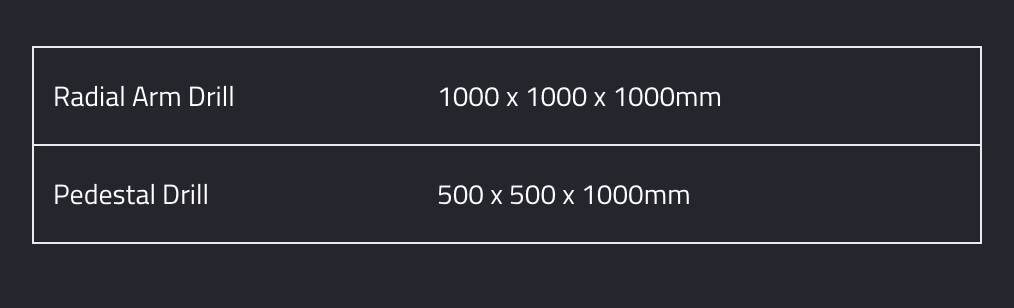

Drill Machines

Our drill machines are specifically designed to be able to maneuver around large pieces and components. The large parts can either be mounted on tables or bolted to the ground while we work on them.

When is Large Component Machining Useful?

Below are some examples of large component machining that we have worked on for our clients:

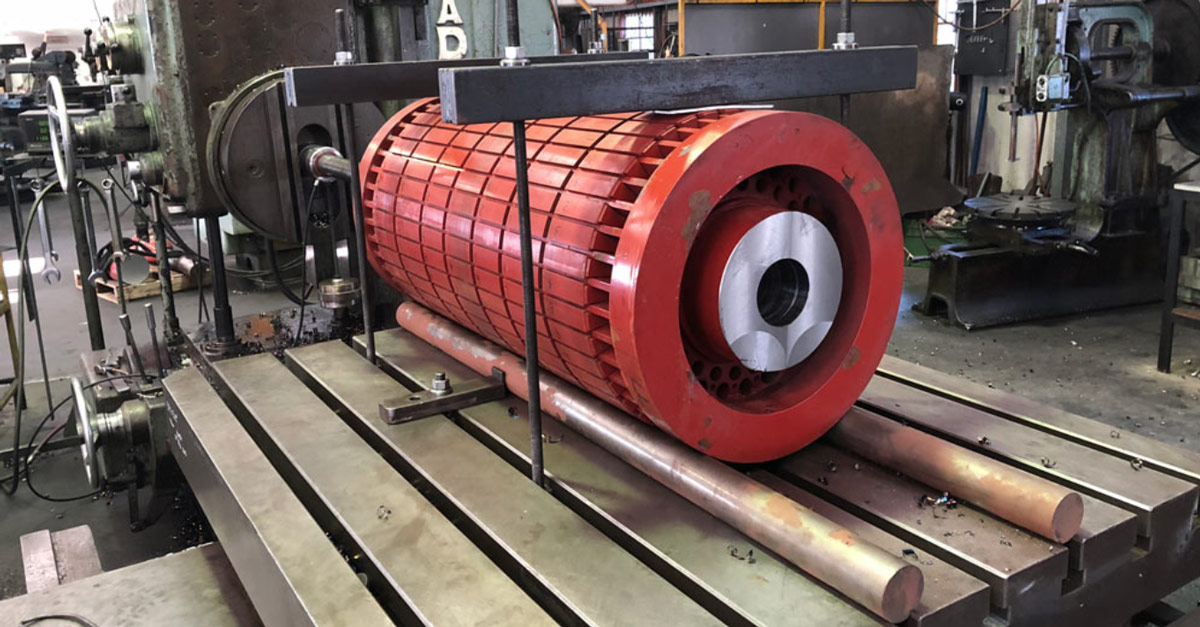

Large Electric Motor Rotor Core

In this case, the damaged shaft was being bored out in order to put a replacement shaft on the borer. These shafts require massive amounts of force in order to press them out (approx 800-ton pressure). When pressing out, major damage can occur to the rotor core and this is the most expensive part of the unit so a job like this requires great precision and care. This particular borer came from a mining site.

Large electric motor shaft

This is the large electric motor shaft that went in the above motor rotor core. After the damaged shaft was being bored out, this shaft was made as a replacement but fitted in the core with liquid nitrogen as requested by the customer.

Large 500mm dia lock nut

This 500mm dia lock nut was turned from a solid billet of steel on a large lathe and the sections were machined on the outer dia of the borer to aid installation. This nut fits onto the wheel main drive spindle of a CAT793 dumper truck.

At Prime Engineering, we can use large component machining for both repairs and fabrication in a large range of industries and projects. To learn more about our engineering services or how we can provide you with an engineering solution, don’t hesitate to get in touch with us!