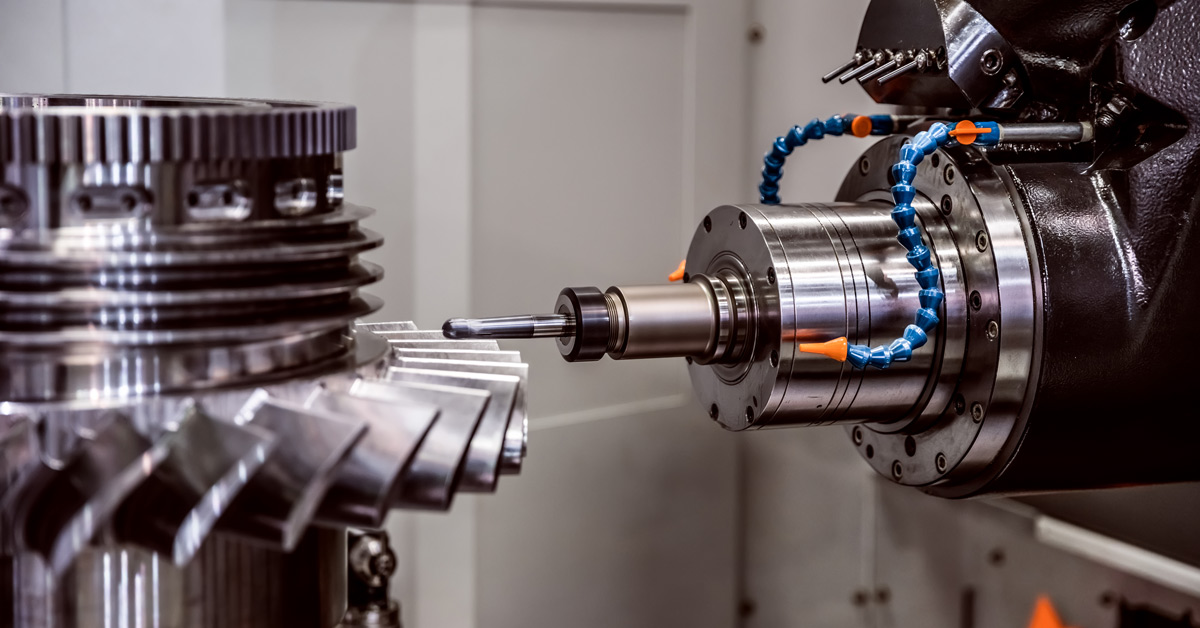

For a long time, any machining work was done on a mill, by hand. While precise tolerances are achievable, it took time, and in every industry, time = money! The manufacturing industry is now undergoing a transformation as we are propelled into the fourth industrial revolution, and this transformation is the digitalisation. What does this mean? Well, after a CNC design is done in CAD, it is then converted into numbers, which allow a cutting tool to carve the object based on coordinates. Prime Engineering is on of Brisbane’s leading precision machining specialists, and we’ve seen first hand how CNC machining transforms the production process.

Speed and production times

Since the CNC process is automated once the design is finished, production times are reduced significantly since manual labour isn’t required to complete the machining. Batches of machining can be completed with the operator simply loading and unloading the units from the machine. The ability to produce considerable quantities of precision-crafted parts has equated to savings on what previously required many labour hours to produce.

Accuracy

While human error is avoided as best as possible, it is always expected and often occurs in large machining projects. CNC machining practically eliminates human error and can achieve accuracy within 0.0001. This is unrivalled and truly changes how workmanship is seen in the fourth industrial revolution.

Reliable endurance

CNC machines are precisely that: machines. They can work around the clock, daily, with little to no downtime. Preventative maintenance is advised to avoid having costly downtime due to repairs. Scheduled repairs can be worked around, but unplanned breakdowns will cost time and money, so avoid risking them.

More capability

When coupled with advanced design software, CNC machining outputs cannot be matched by manual machines. Even the older blokes who have been on the tools their whole life can’t match what a CNC machine is capable of. These machines are able to produce any shape, size and texture, without fail.

Uniform product

CNC machining has the ability to provide repeatable results over and over, compared to the variability of operating manual machines. Expert engineers are able to machine components that are very close in specs, but they vary slightly. CNC machining provides an exact production of specifications used.

Fewer headaches

Manual machining is excellent in many ways, but it will always be susceptible to human error. We all know how painful and costly it can be when you’re down on team members and production of parts halts to a grinding stop due to lack of staff. CNC machining eliminates this problem, and multiple machines can be run by just one operator if they’re well trained.

As with the introduction of any moderately new technology, learning the new tech is a crucial element of introducing it to your workforce. CNC has its benefits, and we’ve seen its ability to transform the large parts production process at Prime Engineering. We’re your partners in engineering, and we can provide the large parts precision machining to ensure everything in your machine can operate just as it should. Get in touch with us now to talk about your project!