OUR EXPERIENCE

REDESIGNING COMPONENTS

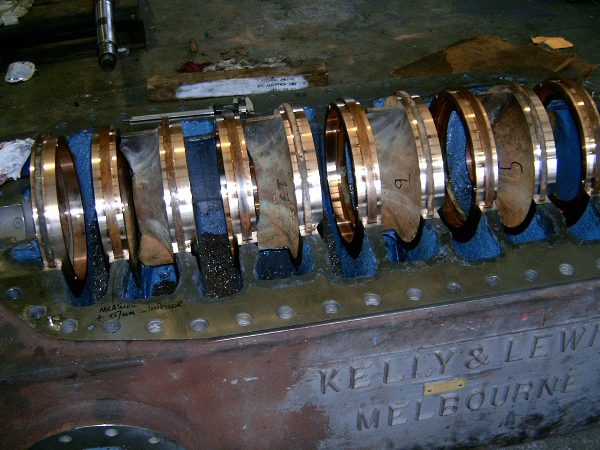

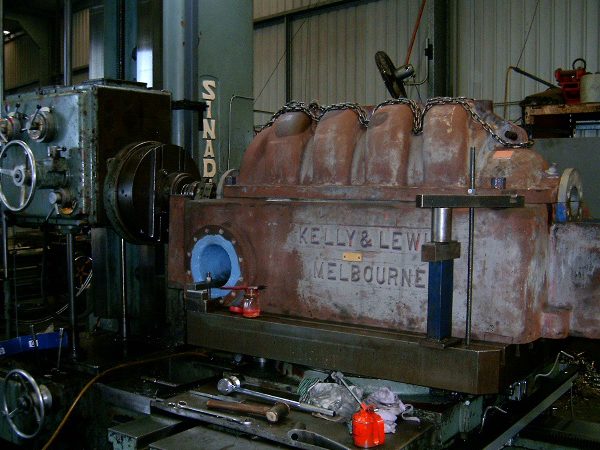

5 STAGE SPLIT CASE PUMP

The Prime Engineering team recently put their heads together to solve another challenge! This time, we were approached by a client looking to rebuild a 5 Stage Split Case Pump.

The Challenge:

The client’s pump had reliability issues, poor efficiency, a short service life and unreasonably long refurbishment lead times. We were asked to improve the internal component design and materials to improve the aforementioned issues. We also streamlined the manufacturing process and created a quality assurance procedure so parts could be interchangeable with any other pumps that were built in the future.

We also had to supply all machined parts in a 5-6 week lead time, keep costs under previous repairs, and produce parts to a higher quality and tolerance than previously done.

It was a tall order. But, with our design and machining capabilities, we were confident that we could outperform previous rebuilds and secure more pumps for the future knowing there were more of these pumps in service.

So, we got to work…

The Results:

- Successful documentation and component improvement.

- We were able to line bore and manufacture all internal parts as per the redesign.

- We supplied all of the parts to the client within the expected time frame and costs.

- Our client assembled the pump with no issues.

- Our client’s initial feedback was that the pressure and flow rates were higher than ever before. The long term feedback we received was that the pump had a much longer service life than previous pumps too.

- As a result, we have now completed more than twenty 5 Stage Split Case Pumps over several years for our client with no warranty claims.